In hodiernae industriae productio landscape, efficientiam et industria conservationem facti sunt pivotal benchmarks ad aestimandis apparatu perficientur. As a high-efficiency heat exchange component, the H-type fin tube , with its unique design and exceptional performance, plays a vital role in numerous fields. Ita, inter universa ordinata de foro postulat, quam exacte debet unum mos an h-type fi fistulam calorem exchanger quod aligns perfectly cum sua industriae necessitatibus?

Design Advantages of H-Type Fin Tubes and Their Industrial Applications

The design philosophy of H-type fin tubes cleverly merges high-efficiency heat transfer with structural optimization. H-Fin structuram et distinctivum duas symmetriis pinnulas-sunt firmiter conflatum utrinque utrinque basi tubo per altus frequency resistentia welding. Hoc non solum significantly auget externum calorem, accepto area sed etiam gignit turbine ut airflow transit per efficaciter disrupting terminus accumsan et sic dramatically enhancing calor commutatio efficientiam.

Traditional spiralis fin tubulis, h-genus fistulas iactare minus in minore windward regio et inferioribus Fluue Gas resistentia ad idem calor commutationem regio. Hoc praecipue crucial ad boiler economents qui confidunt in Flue Gas vastitatem calor, ut possit efficaciter reducere fan industria consummatio et consequi industria savings. Praeterea, in auto-Purgato proprietas H-genus fists fistulas est insignis, eorum structura est minus prone pulveris cumulus per operationem, extendens apparatu sustentacionem cyclis et enhancing operational stabilitatem. This makes them especially suitable for environments with complex flue gas conditions, such as pulverized coal furnaces and biomass boilers.

Manufacturing Process and Key Technologies for Custom H-Type Fin Tubes

Behind a qualified H-type fin tube product lies a rigorous and precise manufacturing process supported by advanced technologies. Customizing H-genus fists incipit cum accurate consilio fundatur in clientis scriptor specifica operating conditionibus, inter fluidum medium, temperatus, pressura, fluunt rate et installation spatium. These parameters determine critical features such as fin height, thickness, pitch, and the material and dimensions of the base tube.

Deinde est crucial welding scaena: summus frequency resistentia Welding est angularis de ensuring qualis est vinculum inter pinnas et basi fistulam. Hoc technology utitur summus frequency current ad generare vehemens calor, statim fingit pinnulas et basi fistulam absque impletiones formare fortis metallurgical vinculum. Hoc modo non solum delivers princeps iuncturam vires sed etiam minimizes calor-affectus zone, ne structural mutationes in basi fistulam ex altum temperaturis et sic servare mechanica proprietatibus.

Moreover, strict quality control runs through the entire production process to ensure long-term reliability. Hoc includit chemical compositionem temptationis rudis materiae, weld inspectionem de fin tubulis, et hydrostatic temptationis complevit products-omnes ad praestare quod omne h-type fi fistulam relinquens officinas occurrit restrictius operational.

Key Factors Influencing Heat Exchange Efficiency of H-Type Fin Tubes

The heat exchange efficiency of H-type fin tubes is not fixed; it is influenced by a combination of factors. Uno modo, Fin Geometrica parametri formare fundamentum calor translatione euismod: fin altitudo et crassitudine directe afficit calor commutationem area et æstus transitus in airflow alveus. An overly parvum picem, quamquam augendae area, ut faciam auctus flue Gas resistentia vel etiam cinis blue, ultimately reducing altiore efficientiam.

Secondly, fluid properties—such as flue gas composition, flow rate, and temperature—exert a significant impact. Higher flow rates enhance turbulence and heat transfer coefficients but also increase pressure loss. Thus, comprehensive thermodynamic calculations and fluid dynamics simulations are essential during design to strike the optimal balance.

Finally, material selection is equally critical. Different operating conditions demand varying levels of corrosion and high-temperature resistance. For example, in flue gas environments with sulfur corrosion, choosing corrosion-resistant alloy steel tubes can effectively extend service life. All these factors must be thoroughly considered during the custom design phase.

Application Cases of H-Type Fin Tubes in Diverse Industrial Scenarios

H-type fin tubes have excelled in numerous industrial fields thanks to their outstanding comprehensive performance. In boiler vestibulum, sunt late in Economizers ut Preheat Boiler Peasewater usura vastum calor a boiler cauda, ita improving boiler scelerisque efficientiam et salutaris cibus.

In petrochemical industria, h-type fistulas fistulas invenies applicationem in convection sectiones heaters vel fregisset furnas, recuperandis calor ex summus temperatus flue Gas ad preheat processu fluidorum. In waste heat recovery, whether from kiln head/tail waste heat in cement plants or flue gas from glass furnace melting chambers, H-type fin tube heat exchangers serve as core equipment, efficiently converting industrial waste heat into usable energy and bringing significant economic and environmental benefits to enterprises.

Hae felix applications plene demonstrabo flexibilitate et adaptability H-genus fistulas, solidifying eorum munus quod necessaria calor commutationem components in modern industria.

Future Development Trends in Custom H-Type Fin Tubes

Ut industria 4.0 et viridis vestibulum conceptus progredi, in futurum H-genus fists focus magis in intelligentia, princeps efficientiam et environmental amicitia. Cras est H-genus fistulas ut integrate magis intelligentes sensoriis ad Monitor apparatu operatio in real-vicis, mores magna notitia analysis et enable predictive sustentacionem.

Eodem tempore, in application of novus materiae, ut composites vel superficiem coating technologiae, erit amplius augendae eorum altus-temperatus et corrosio resistentia, expanding eorum range of applications. Praeterea, progressiones in calor exchanger consilium software et simulatio technologiae mos faciet mos consilio magis precise et efficiens, permittens propter citius respondeo magis cost-efficax, summus perficientur solutions ad industriae productio.

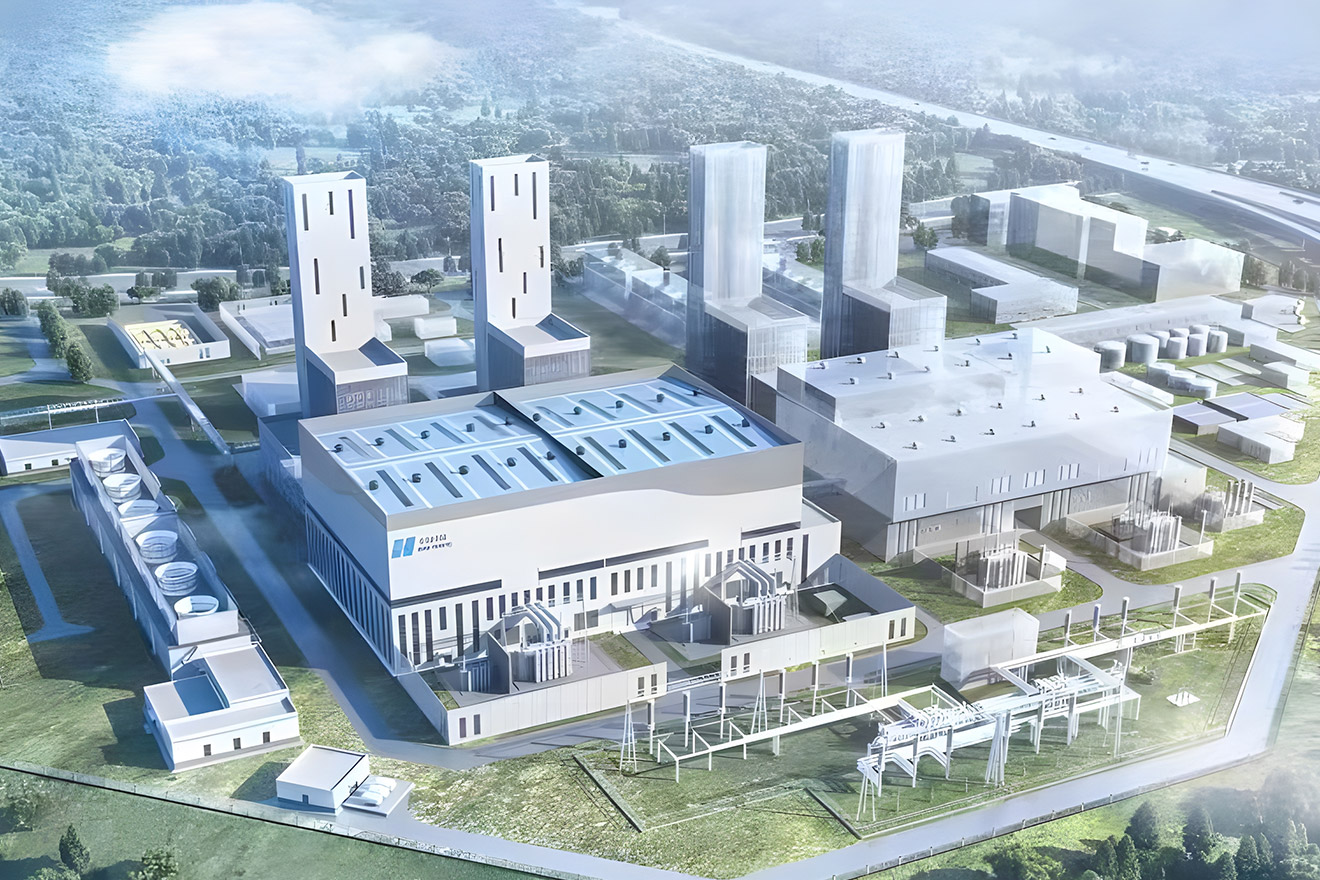

H / J PDF HRSG BoilerMHL Power Dongfang Boiler Co., Ltd. (MHDB) est superbia ad launch eius diligenter ficti h / j gen...

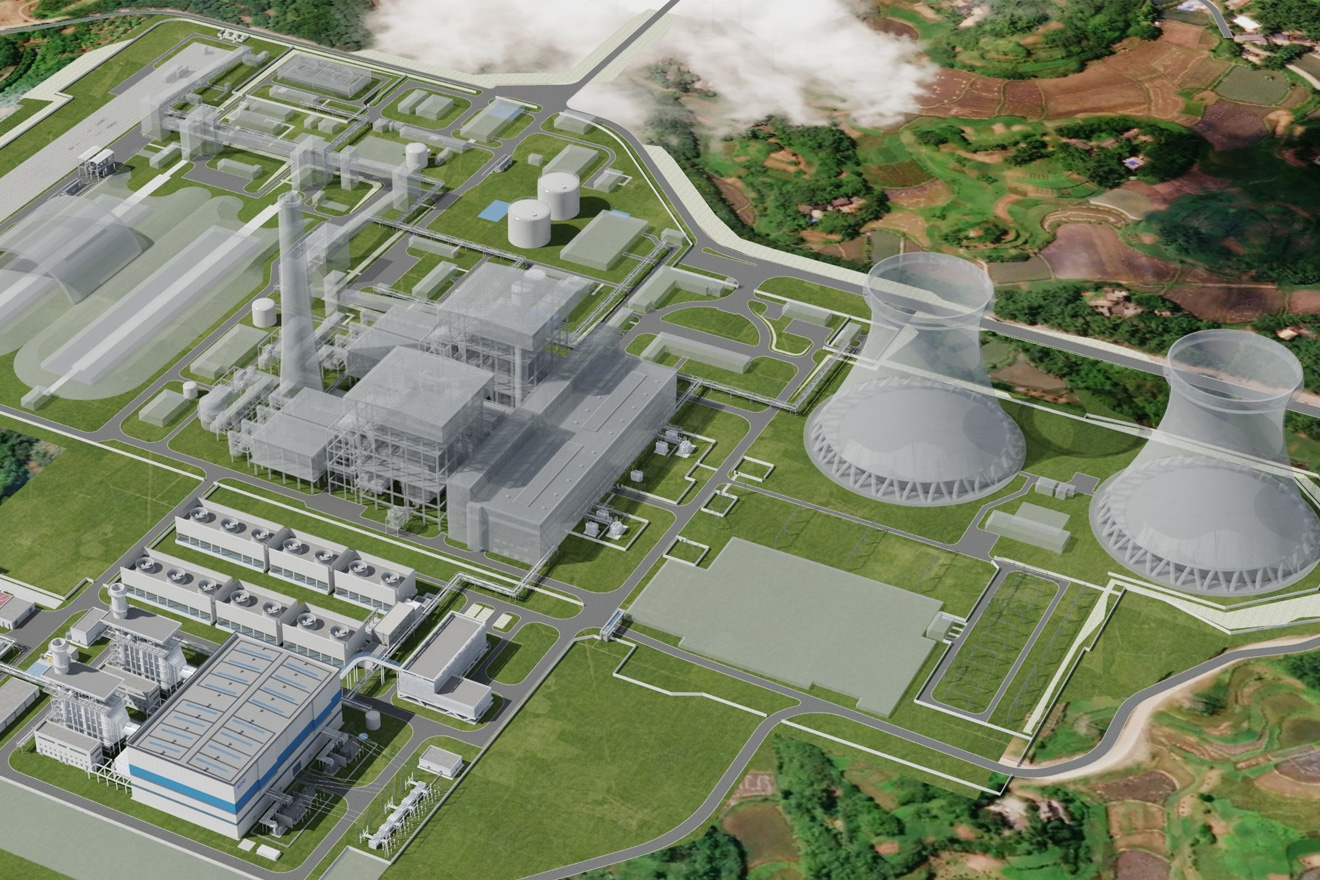

H / J PDF HRSG BoilerMHL Power Dongfang Boiler Co., Ltd. (MHDB) est superbia ad launch eius diligenter ficti h / j gen... F PDF Hrsg BoilerIn F PDF HRSG, Ingenly Built by MHL Power Dongfang Boiler Co., Ltd. (MHDB), factus est princeps i...

F PDF Hrsg BoilerIn F PDF HRSG, Ingenly Built by MHL Power Dongfang Boiler Co., Ltd. (MHDB), factus est princeps i... E Class & Inferius Hrsg BoilerUsing provectae et radialis calor serie technology, in layout de calefacit superficiem est pressi...

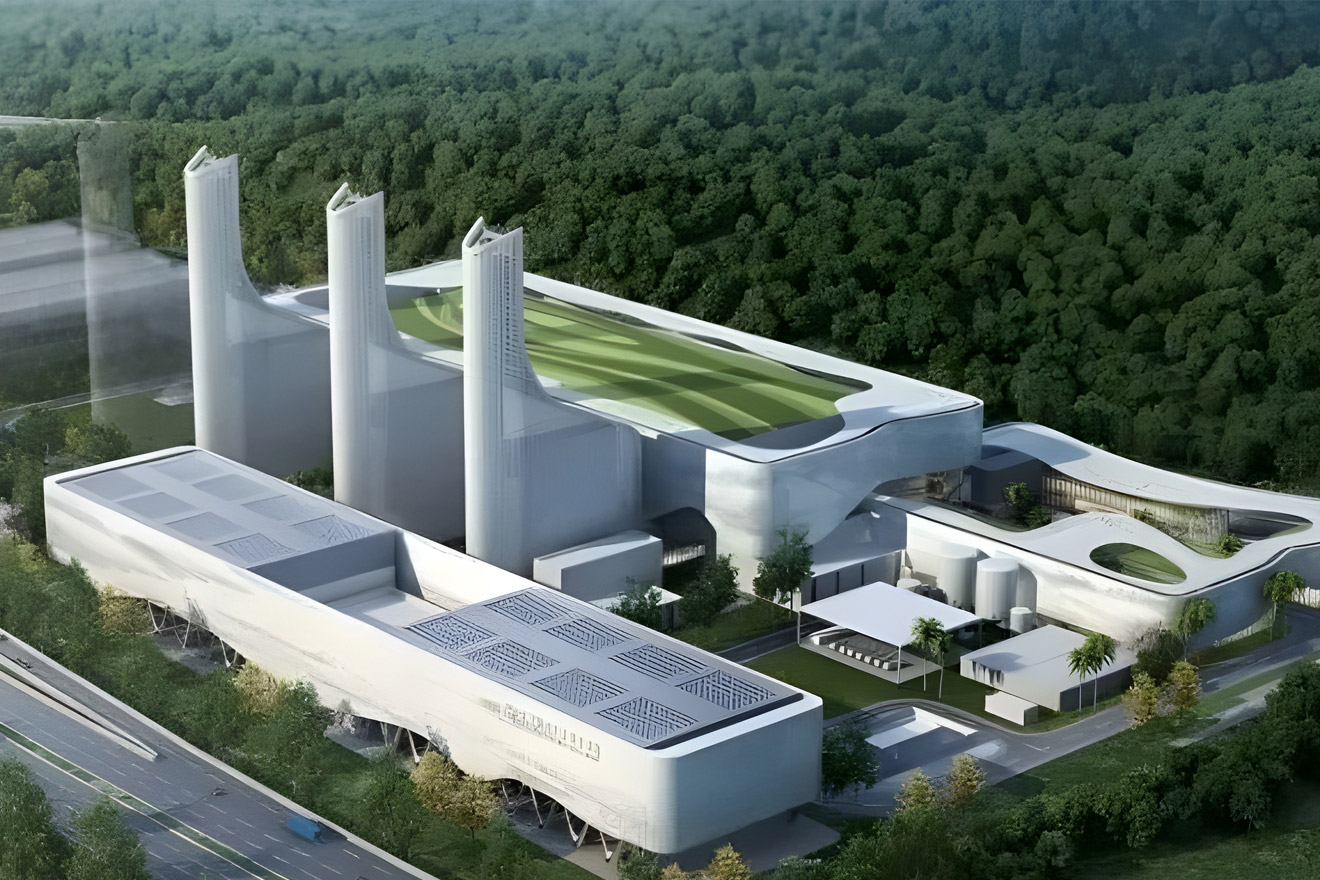

E Class & Inferius Hrsg BoilerUsing provectae et radialis calor serie technology, in layout de calefacit superficiem est pressi... Perdere ad industria (WTE)- municipales solidum desertum incineratio boiler - eget vastum incineratio boiler - Medical perdere incineratio Boiler

Perdere ad industria (WTE)- municipales solidum desertum incineratio boiler - eget vastum incineratio boiler - Medical perdere incineratio Boiler Municipales solidum vastum incineratio Boiler (WTE)Et municipales solidum vastum incineratio Boiler Professionally developed et produci a MHL Power ...

Municipales solidum vastum incineratio Boiler (WTE)Et municipales solidum vastum incineratio Boiler Professionally developed et produci a MHL Power ... Chemical vastum incineratio Boiler (WTE)MHL Power Dongfang Boiler Co., Ltd. (MHDB), ut a ducens turba in agro de ancipitia chemical vastu...

Chemical vastum incineratio Boiler (WTE)MHL Power Dongfang Boiler Co., Ltd. (MHDB), ut a ducens turba in agro de ancipitia chemical vastu... Medical perdere incineratio Boiler (WTE)MHL Power Dongfang Boiler Co., Ltd. (MHDB) habet diligenter aedificavit professional medicinae va...

Medical perdere incineratio Boiler (WTE)MHL Power Dongfang Boiler Co., Ltd. (MHDB) habet diligenter aedificavit professional medicinae va... Alii boiler- Benson semel-per boiler - Naturalis circulationem tympanum boiler - Special Boiler

Alii boiler- Benson semel-per boiler - Naturalis circulationem tympanum boiler - Special Boiler Benson semel-per boiler (300mw et supra)Cicero semel-per Boiler (300mw et supra) usum provectus direct-fluxus combustione technology, et ...

Benson semel-per boiler (300mw et supra)Cicero semel-per Boiler (300mw et supra) usum provectus direct-fluxus combustione technology, et ... Naturalis circulationem tympanum boiler (200mw et infra)MHL Power Dongfang Boiler Co., Ltd. (MHDB), ut a duce in industria apparatu vestibulum, focuses i...

Naturalis circulationem tympanum boiler (200mw et infra)MHL Power Dongfang Boiler Co., Ltd. (MHDB), ut a duce in industria apparatu vestibulum, focuses i... BOILLERMHL Power Dongfang Boiler Co., Ltd. (MHDB), sicut ducit manufacturer in agro speciali Boiler, in ...

BOILLERMHL Power Dongfang Boiler Co., Ltd. (MHDB), sicut ducit manufacturer in agro speciali Boiler, in ... Service - Power upratisH-genus fistula fistula adoptatus mico resistentia welding technology, welding duo quadratum ferro laminis circularibus arcus hiatus in medio ad nudum fistulam. H-genus Finded fistulam habet sequentes, -Excellent æstus transitus efficientiam -Small fluxus resistentia Fluue Gas -Good A...

Service - Power upratisH-genus fistula fistula adoptatus mico resistentia welding technology, welding duo quadratum ferro laminis circularibus arcus hiatus in medio ad nudum fistulam. H-genus Finded fistulam habet sequentes, -Excellent æstus transitus efficientiam -Small fluxus resistentia Fluue Gas -Good A... H-genus Finded TubeH-genus fistula fistula adoptatus mico resistentia welding technology, welding duo quadratum ferr...

H-genus Finded TubeH-genus fistula fistula adoptatus mico resistentia welding technology, welding duo quadratum ferr...

LENTITUDO

LENTITUDO